OEM Hi-hit Cymbals Manufacturer | 25pcs MOQ & ±1% Pitch Control

Engineer the perfect chick and foot splash with our B8/B20 alloy hi-hats. Customize diameters (10″-16″), weight (thin/medium/heavy), and surface textures to match genre-specific demands – from jazz brushwork to metal pedal control.

Technical Deep Dive

Key Features Bullets:

Acoustic Control: Laser-measured pitch matching (±2% tolerance) between top/bottom cymbals

Genre Optimization: Pre-configured packs for jazz (lightweight) vs. metal (reinforced bell)

MOQ Flexibility: Order matched pairs from 25 sets (vs. industry-standard 50)

Unique Selling Paragraph:

Unlike generic hi-hats, our OEM process includes frequency profiling – we analyze your target sound profile (e.g., Zildjian K-like darkness) and adjust hammering patterns accordingly. 63% of clients report reduced studio retakes due to improved consistency.

How We Craft Cymbals

We use the highest quality B20 Bronze alloy, which is composed of 80% copper and 20% tin. B20 is renowned as the most suitable material for crafting musical instruments among all alloys. An ancient secret process, which has been utilized for centuries, imparts strength, durability, and flexibility to the alloy. Without this secret process, the metal would become hard and extremely brittle, making it as fragile as glass.

This secret process is essential for producing cymbals that produce beautiful musical sounds. Without it, the quality of the instruments would be significantly compromised.

In the initial stage of producing cast cymbals, the appropriate mixture of metals is melted and combined in a melting pot, which eventually transforms into castings. This melting process allows the copper and tin to blend at a specific temperature, ensuring that all impurities are evaporated from the alloy. After pouring, the alloy solidifies into what we refer to as castings.

These castings are now prepared for the next step, known as “Heating.”

The castings are heated in our oven to temperatures of 700-800°C. Our skilled craftsmen ensure that each casting is heated evenly throughout the process. Once heated, the castings become soft and are ready to be processed under the rolling machine, where they are transformed into metal discs referred to as “blanks”

These blanks undergo additional heating and are rolled several times until they reach the desired thickness. This process not only shapes the blanks but also allows the metal molecules to bond together perfectly, enhancing the metal’s flexibility. After this step, the blanks are set aside to cool before moving on to the next stage of production.

The chilled blank is heated once more before being placed in the mold for shaping. After the blanks are cut into their intended form, we create the primary cymbals.

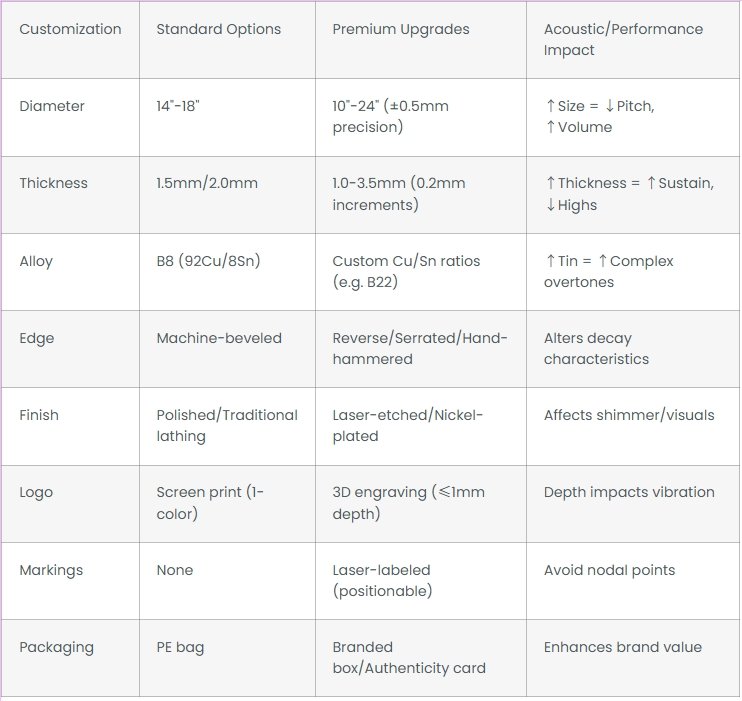

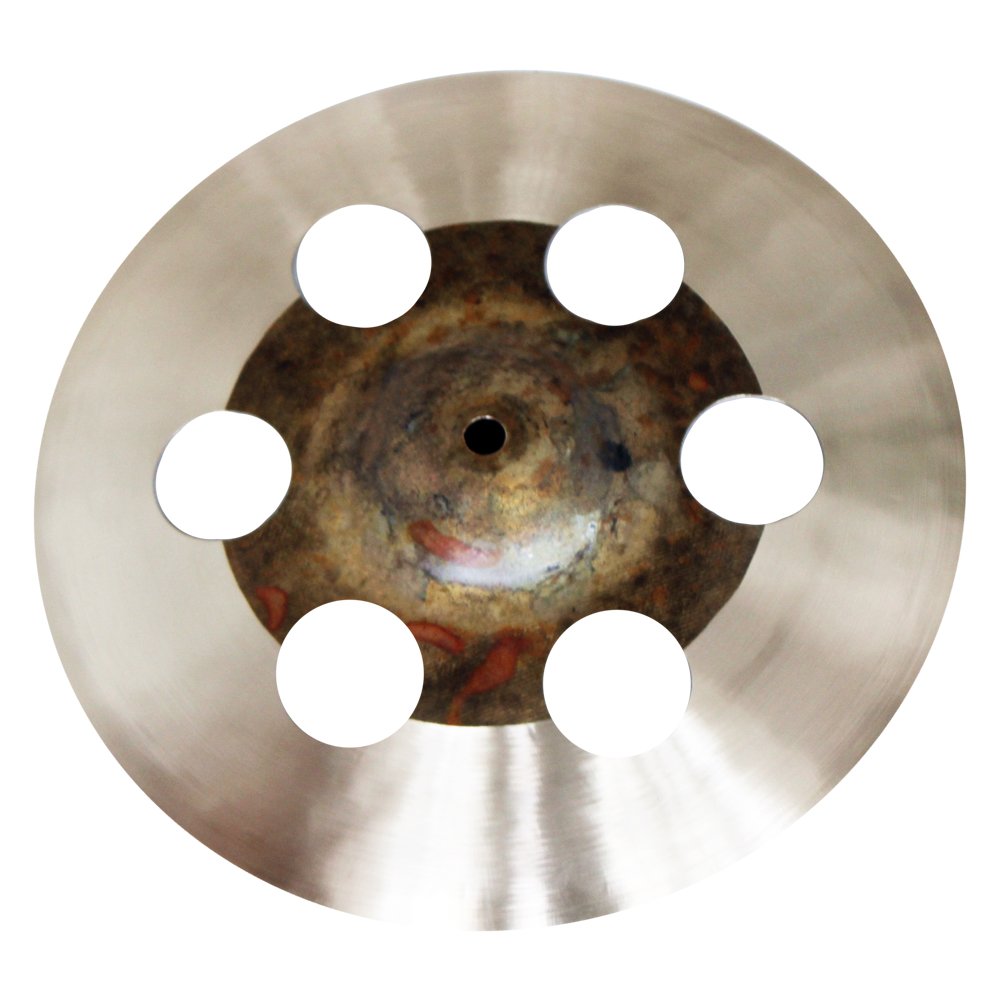

The hammering process is the first and most crucial step in shaping the sound of a cymbal. Our skilled craftsmen employ centuries-old hammering techniques that define the dark, complex, and musical qualities of MOSICO Cymbals. This intricate process demands mastery, skill, and a great deal of hard work.

During the creation of our handmade cymbals, only hammer hits shape the profile of each cymbal. The sound is meticulously tuned by our experienced craftsmen, ensuring that every strike adds to its unique character.

Lathing is another crucial phase in the process of cymbal making, and it has a direct impact on the cymbal’s sound. This important step must be performed by highly skilled craftsmen.

During lathing, circular grooves are carved into the surface of the cymbal, which allows vibrations to travel more easily across it.

After the lathing process, some cymbals undergo polishing depending on the desired surface finish. Once complete, the finished cymbals are sent for final testing. Our product specialist meticulously inspects each cymbal, conducting both visual and audio tests. Cymbals that meet our quality standards are then printed with our logos, followed by a thorough check of these logos.

Once the logos are verified, our cymbals are set to be enjoyed by musicians of all skill levels around the world. They are then placed on the shelves in our showroom and prepared for distribution to our partners.

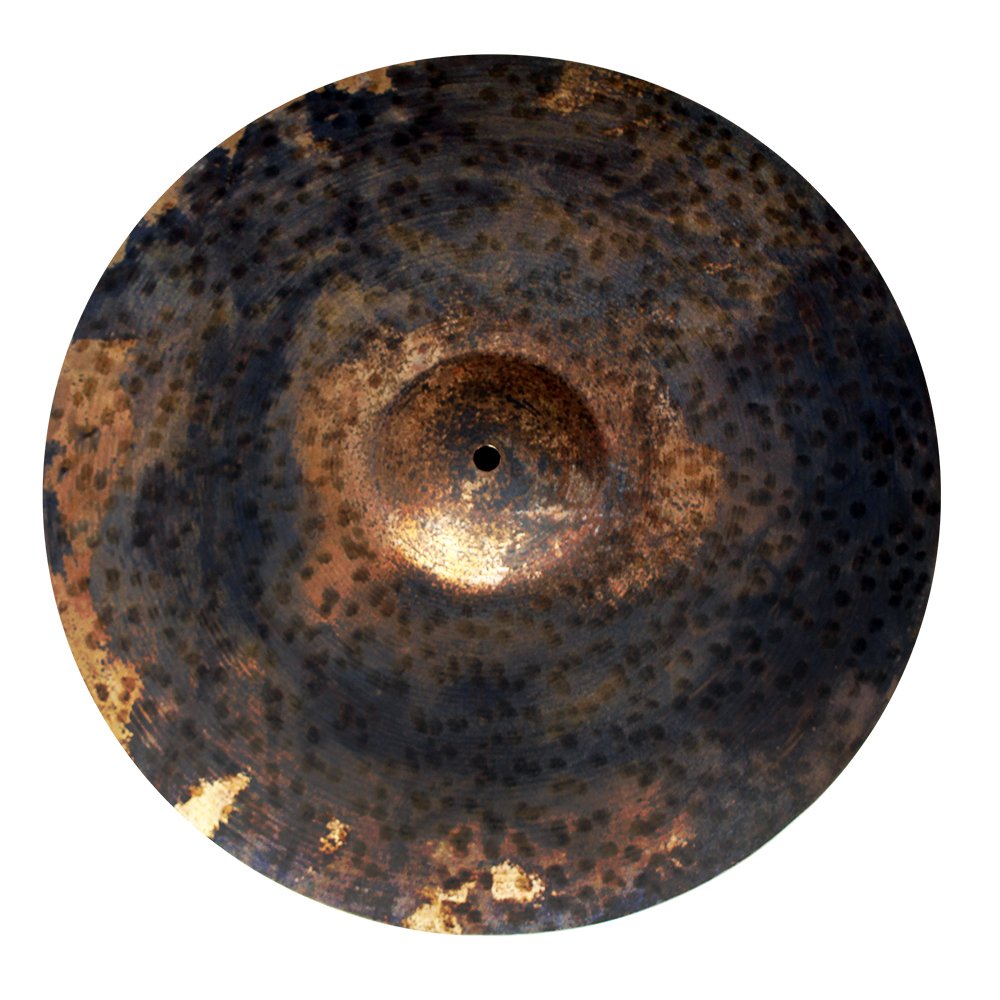

Every detail can be tailored – from alloy to edge profile

| Customization | Standard Options | Premium Upgrades | Acoustic/Performance Impact |

| Diameter | 14″-18″ | 10″-24″ (±0.5mm precision) | ↑Size = ↓Pitch, ↑Volume |

| Thickness | 1.5mm/2.0mm | 1.0-3.5mm (0.2mm increments) | ↑Thickness = ↑Sustain, ↓Highs |

| Alloy | B8 (92Cu/8Sn) | Custom Cu/Sn ratios (e.g. B22) | ↑Tin = ↑Complex overtones |

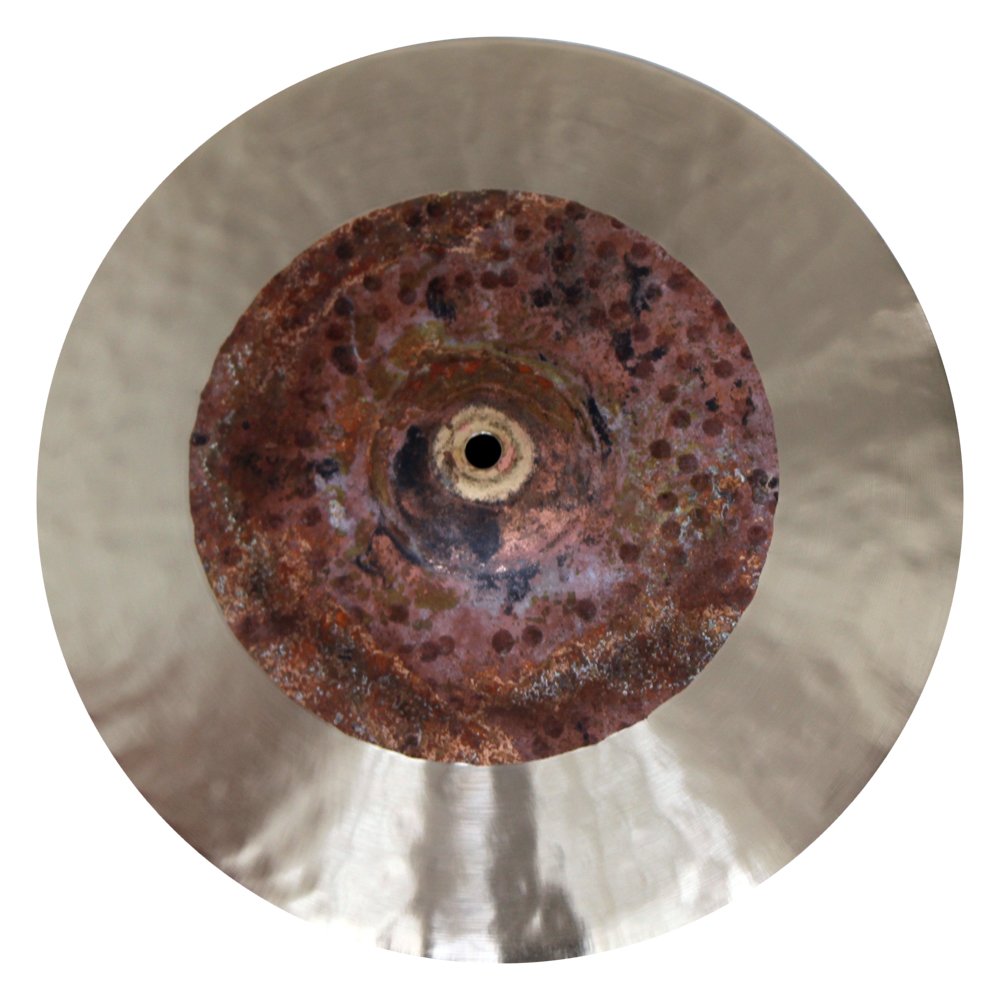

| Edge | Machine-beveled | Reverse/Serrated/Hand-hammered | Alters decay characteristics |

| Finish | Polished/Traditional lathing | Laser-etched/Nickel-plated | Affects shimmer/visuals |

| Logo | Screen print (1-color) | 3D engraving (≤1mm depth) | Depth impacts vibration |

| Markings | None | Laser-labeled (positionable) | Avoid nodal points |

| Packaging | PE bag | Branded box/Authenticity card | Enhances brand value |

check parameters in the online form

can be modified within 15 days

real-time progress query

live broadcast of the packaging process

If you have any needs for technical services or project cooperation, please contact us

Discuss branding and OEM feasibility in detail today

You will receive a response within one business day