You’ll find that cymbal alloy selection stands as a critical factor in your manufacturing decisions, with B20 and B8 representing distinctly different approaches to acoustic performance. These copper-tin formulations shape not only the final sound characteristics but also influence your production methods, quality control protocols, and market positioning. As you examine the molecular structures and mechanical properties of these alloys, you’ll uncover why specific compositions yield particular tonal signatures.

Key Takeaways

B20 alloy contains 80% copper and 20% tin, requiring 1742°F casting temperature and delivering complex overtones with extended sustain.

B8 alloy features 92% copper and 8% tin, cast at 1832°F, producing brighter tones with faster decay suitable for high-volume settings.

Manufacturing B20 demands stricter metallurgical controls and multi-stage forging, while B8 focuses on durability and consistency in production.

B20 cymbals target professional markets with higher price points, while B8 serves entry-level segments with cost-effective manufacturing processes.

Quality testing protocols differ: B20 emphasizes sound characteristics and grain structure, while B8 prioritizes durability and stress resistance.

Understanding B20 and B8 Alloy Compositions

Bronze alloys B20 and B8 represent distinct metallurgical formulations used in cymbal manufacturing, with their names derived from their respective tin content percentages. B20 properties include a composition of 80% copper and 20% tin, creating a dense, resonant material that’s become the industry standard for professional-grade cymbals. You’ll find this alloy delivers complex overtones and exceptional sustain due to its higher tin content.

In contrast, B8 benefits stem from its 92% copper and 8% tin composition, resulting in a brighter, more immediate sound. This alloy’s lower tin content makes it more economical to produce while maintaining durability. You’ll notice B8’s molecular structure creates a focused, cutting tone that’s particularly effective in contemporary music genres. The reduced tin percentage also means these cymbals can withstand aggressive playing styles while maintaining their structural integrity, making them ideal for beginners and intermediate drummers.

Sound Characteristics and Tonal Differences

When comparing B20 and B8 cymbals, you’ll notice B20’s higher tin content produces brighter initial attacks and more articulate stick definition, while B8’s higher copper ratio creates a more immediate, focused response. The molecular structure of B20 allows for longer sustain times and gradual decay curves, producing rich harmonic layers that evolve throughout the cymbal’s resonance period. You’ll find B8’s simpler metallurgical composition generates fewer overtones and a more direct, predictable sound character that emphasizes fundamental frequencies.

Brightness and Attack Profile

The distinct atomic structures of B20 and B8 alloys create fundamentally different acoustic profiles. You’ll notice B8’s higher copper content produces brighter initial tones with a faster attack response, while B20’s increased tin percentage yields more complex overtones that develop more gradually.

| Property | B20 Alloy | B8 Alloy |

|---|---|---|

| Initial Brightness | Moderate | High |

| Sustain Brightness | Complex | Simple |

| Attack Speed | Gradual | Quick |

| Wave Formation | Layered | Direct |

When striking these cymbals, you’ll find B8’s crystalline structure generates immediate, piercing highs that quickly dissipate. B20’s more refined grain structure creates a darker fundamental tone that builds into rich harmonic layers. This difference in atomic arrangement affects not just the brightness levels but also how quickly the sound waves propagate through the metal.

Sustain and Decay Times

Examining sustain profiles reveals stark differences between B20 and B8 alloys, with each composition producing distinct decay patterns. You’ll find that B20’s higher tin content (20%) creates longer sustain duration, allowing sound waves to resonate through the metal with less internal dampening. The complex overtones persist noticeably longer compared to B8 cymbals.

B8’s lower tin percentage (8%) results in faster decay characteristics, where the initial attack quickly shifts to a shorter sustain phase. While you’ll experience a more immediate sound response with B8, the overall sustain length is abbreviated. This rapid decay can be advantageous in high-volume situations where you need quick sound dissipation, but it won’t deliver the extended shimmer that B20 alloys provide in quieter passages.

Complex Overtone Development

Complex overtone structures between B20 and B8 alloys diverge substantially due to their molecular composition and crystalline arrangement. You’ll notice that B20’s higher tin content (20%) creates a denser crystalline matrix, producing richer overtone harmonics and more intricate sound waves. The molecular bonds in B20 allow for greater tonal complexity as the cymbal vibrates.

B8’s lower tin percentage (8%) results in a more uniform grain structure, generating fewer competing frequencies. When you strike a B8 cymbal, you’ll hear more focused, immediate overtones with less layered development over time. The simpler molecular arrangement produces clearer fundamental notes but sacrifices the nuanced secondary and tertiary harmonics that characterize B20’s sophisticated sound profile.

Manufacturing Processes and Technical Considerations

Through precise metallurgical control, manufacturers create B20 and B8 cymbal alloys using distinct casting and forging processes. The manufacturing techniques involve carefully controlling temperature, pressure, and working time to achieve ideal grain structure and molecular alignment. You’ll find that B20’s higher tin content requires more sophisticated alloy processing methods compared to B8’s simpler composition.

- Casting temperatures must be precisely regulated – B20 requires 1742°F while B8 needs 1832°F for proper molecular distribution

- Multi-stage hot and cold forging helps develop the crystalline structure that determines tonal characteristics

- Surface treatments and hammering patterns are tailored specifically to each alloy’s molecular properties

- Quality control measures include x-ray diffraction testing to verify proper grain alignment

The technical complexity of manufacturing these alloys directly impacts their acoustic properties. B20’s sophisticated processing yields more nuanced overtones, while B8’s streamlined production creates bright, focused sounds.

Cost Analysis and Production Efficiency

Production costs between B20 and B8 cymbals diverge considerably due to their distinct material compositions and manufacturing requirements. When you’re evaluating manufacturing expenses, B20’s higher tin content (20%) drives up material costs substantially compared to B8’s 8% tin composition. You’ll find that B8’s lower material costs translate to more economical production runs and higher profit margins.

In your cost evaluation, consider that B20’s complex metallurgical properties require more precise temperature control and longer processing times during casting and tempering. B8’s simpler alloy structure enables faster production methods and reduced energy consumption. You’ll need fewer quality control checkpoints with B8, as it’s less prone to casting defects and microstructural variations. However, the trade-off appears in the final product, where B20’s superior acoustic properties often justify its higher production costs, particularly for premium cymbal lines targeting professional musicians.

Market Positioning and Target Demographics

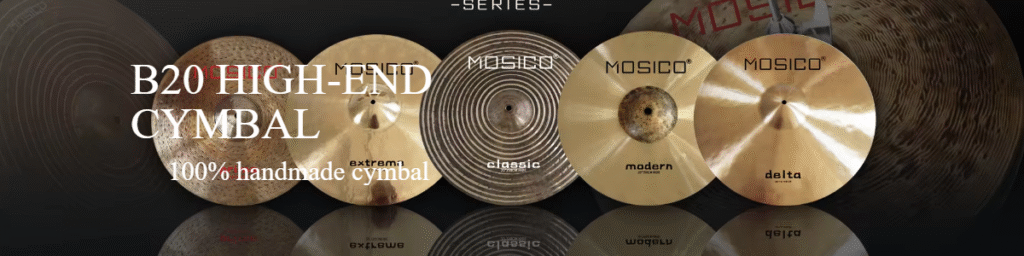

Understanding market segmentation between B20 and B8 cymbals reveals distinct positioning strategies based on material properties and user expectations. Market trends show B20’s premium positioning appeals to professional musicians and serious enthusiasts seeking refined tonal characteristics, while B8’s value proposition targets entry-level and intermediate players.

- B20 cymbals (80% copper, 20% tin) command higher price points in professional music stores and specialty retailers, aligning with buyer preferences for complex overtones and superior sound projection

- B8 alloy products (92% copper, 8% tin) dominate the beginner-to-intermediate market segment through music education suppliers and general instrument retailers

- Demographics for B20 users skew toward established performers, recording artists, and touring professionals requiring superior acoustic properties

- B8’s target market includes students, worship teams, and recreational musicians who prioritize durability and cost-effectiveness over subtle tonal nuances

Your market positioning should consider these established segmentation patterns when developing product lines and distribution strategies.

Quality Control and Performance Testing

Quality control measures for B20 and B8 cymbal alloys follow distinctly different testing protocols based on their material composition and intended market applications. You’ll need to implement rigorous quality assurance procedures, focusing on hardness testing, resonance analysis, and alloy composition verification for both types.

For B20 cymbals, you must conduct grain structure analysis and perform frequency response measurements across multiple points to guarantee consistent tonal characteristics. The higher tin content requires stricter metallurgical controls during the manufacturing process. In contrast, B8’s quality control emphasizes durability testing and stress resistance due to its harder composition.

Performance metrics for both alloys include decay time measurement, frequency spectrum analysis, and hammer mark consistency evaluation. You’ll want to test each cymbal’s response under various striking forces and verify that overtones align with established benchmarks. Regular material composition testing guarantees your manufacturing process maintains precise alloy ratios throughout production runs.

Conclusion

You’ll find that B20 and B8 alloys represent distinct metallurgical paradigms in cymbal manufacturing. While B20’s higher tin content yields superior acoustic complexity and sustain through enhanced molecular bonding, B8’s copper-dominant structure delivers focused projection with reduced production costs. Your choice between these alloys must balance material properties, manufacturing parameters, and market positioning. The future of OEM cymbal production hinges on optimizing these metallurgical relationships.